Technology

Hardware

Z-Pellet One

It is our standard modular system, with an initial manufacturing area of 3 m³. Designed for production environments requiring precision, reliability and compatibility with technical, recycled or reinforced materials.

Z-Pellet Kompact

The most compact solution, ideal for getting started in large-format additive manufacturing with robots when space is limited. It maintains the same industrial approach, in an optimized and accessible format.

Ad-hoc

We develop systems for specific needs, compatible with any robot brand, workload or control system. We design each solution according to the customer's process and application.

Extruder

Three capacity ranges: 3, 8 and 12 kg/h.

Direct pellet extrusion.

Multi-zone temperature control .

High torque spindle and motor.

Integrated sensors.

Flow and speed adjustable from Laminar.

Interchangeable nozzles.

Integration with any industrial robot.

Wooden base

-

Standard and economical surface for large format printing.

-

Good adhesion with mechanical anchorage.

-

Ideal for prototyping, testing or high tensile materials.

-

Compatible with mechanical fasteners or adhesives

-

Easy disassembly and quick maintenance.

-

Sized according to the customer's printing needs.

- Possibility to install several for different manufacturing areas. Never let your production stop.

Modular heated base

-

Heated surface with temperature zone control from Laminar.

-

Improves adhesion on technical materials and reduces deformations.

-

Interchangeable top plates for different uses or materials.

-

Robust structure prepared for long printing cycles.

-

Recommended for functional parts or short production runs.

Industrial control cabinet

Manufactured in-house, with design and assembly by the Ziknes team.

Siemens industrial PLC, with robust and reliable architecture.

Remote updates, without the need for on-site intervention.

Industrial firewall to protect the system against unauthorized access.

Meets the highest industrial IT security standards.

Full integration with Laminar for real-time control and monitoring.

Ready for demanding industrial environments, with easy maintenance and scalability.

Software

Laminar is the software we have developed at Ziknes to manage the entire large format 3D printing process with industrial robots. From design to production, Laminar takes care of slicing, simulation, path planning and real-time control of all printing parameters.

With a clear and powerful interface, it allows to adapt each job to the material, geometry and manufacturing strategy, with full traceability and direct connection to the control system.

Slicing and control on a single platform

Real-time adjustments and traceability

Integration with hardware and control system

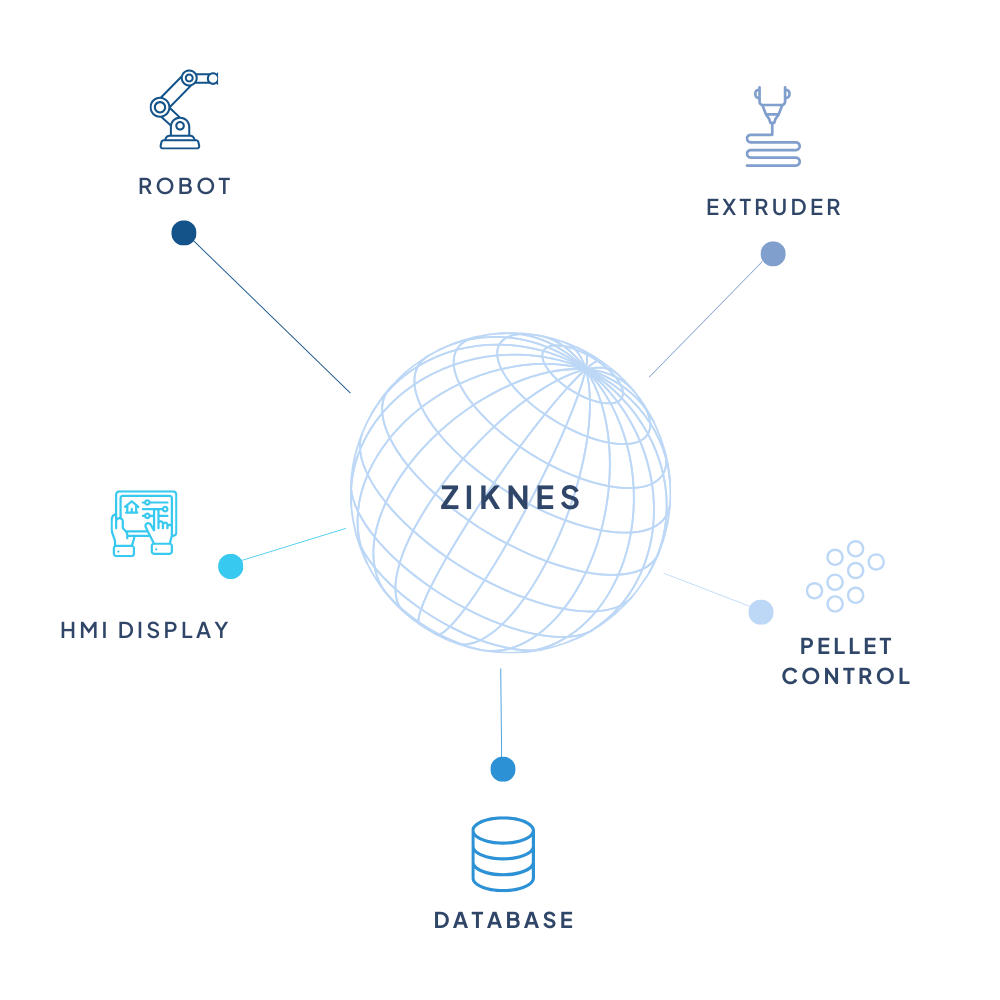

Control

Control system with Siemens PLC, industrial computer and HMI, integrated with Laminar. It allows to adjust parameters in real time, control production, remotely access printing programs and maintain security with firewalls and online updates.

Integration

Connected solutions, close support

We integrate each system with our expert team. We provide knowledge, direct technical support and customized training. We deliver turnkey solutions, ready to produce and tailored to each customer.

Contact with us

Do you need more information or do you want to know Ziknes from the inside?

Contact our team. We want to help you optimize your large format manufacturing processes.

Where we are

Lanzadera Building, Valencia

Numancia de la Sagra, Toledo